Ogden News

WKU engineering students show strength in bridge competitions

- Wednesday, May 28th, 2014

Whether it’s balsa wood or steel, WKU’s Department of Engineering is showing its strength in bridge design and construction.

Civil engineering students start designing and building bridges out of balsa wood during their freshmen year and progress to steel construction as part of senior project work.

WKU civil engineering’s steel bridge team will compete for national honors May 23-24 in the 2014 National Student Steel Bridge Competition at the University of Akron.

“We really teach students a strong work ethic,” said Dr. Shane Palmquist, associate professor and advisor of the WKU steel bridge team. “With projects like the steel bridge or the concrete canoe, students know when the competitions are and it’s up to them to make it happen. It’s up to the students to deliver and they take ownership of the projects.”

Next up for the steel bridge team is the 2014 National Student Steel Bridge Competition. Eight WKU students will compete Friday and Saturday (May 23-24) in the event at the University of Akron.

Steel bridge team members include team co-captains Jacob Martin of Shelbyville and John Jacoby of Paris; Carson Joyce and Chris Sivley, both of Hopkinsville; Nicholas Miller of Bowling Green; Sean Danehy of Libertyville, Ill.; Matt Groves of Greenville; and Noufissa Chbihi of North Haven, Conn.

“Our students are excited about qualifying for the national competition for the second year in a row,” Dr. Palmquist said.

The competition also is generating excitement among underclassmen as they progress toward the senior project, he said.

“We want to get our underclassmen involved because building a legacy is really important,” Dr. Palmquist said.

WKU students Raymond Van Zee of Russellville and Blake Adams of Monticello have been building a legacy of success in balsa wood bridge construction in the past two years with victories in regional competitions.

“They have dominated the balsa wood bridge competition at the Ohio Valley Student Conference the past two years,” said Dr. Warren Campbell, Kenneth E. and Irene S. Hall Professor in Civil Engineering and balsa wood bridge team advisor. “Their bridge this year held more than twice what any other bridge held.”

At the 2014 regional competition, the bridge built by the WKU team held 60.4 pounds while the nearest competitor’s bridge held 20.

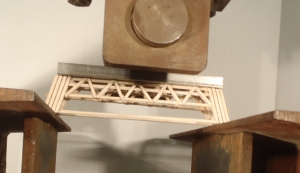

In a recent test, this balsa wood bridge designed and built by WKU students Raymond Van Zee and Blake Adams for a class project held 1,478 pounds before breaking after the loading plate slipped. Faculty member Warren Campbell says the bridge could have held three times more weight.

During the spring semester, Van Zee and Adams designed and built another balsa wood bridge in a strength of materials lab that allowed for a much stronger bridge.

In a recent test in the WKU Engineering Department, Dr. Campbell and the students learned the design was much stronger — holding 1,478 pounds before breaking after the loading plate slipped.

“If the plate had remained aligned, the bridge could have held three times as much,” Dr. Campbell said. “In any case, it was a remarkable job of design and construction.”

How can a small bridge built of balsa wood withstand more than a half ton of weight? “First, we understand the properties of balsa wood and how to estimate the strength of a particular stick of balsa wood,” Dr. Campbell said. “We analyze our designs and optimize them using strong sticks for the parts of the bridge that will be subjected to the greatest loads, and weaker and lighter balsa wood for the parts of the bridge that get the least load. Also, Blake and Raymond construct in a way that minimizes the impact of slight construction errors.”

The team also builds and tests several practice bridges to prepare for the competition’s two-hour construction time limit. “By the time the competition rolls around, they are pretty efficient at construction of the bridge and can build a more complicated design that some other teams,” Dr. Campbell said.

Designing, fabricating and constructing an affordable and efficient bridge also is focus for the steel bridge competition, which is scored on display, construction speed, lightness, stiffness, construction economy and structural efficiency.

The students design the bridge, order steel, cut the steel then have the structure welded. The team then practices constructing the bridge to meet competition time limit and other requirements.

At the Ohio Valley Student Conference in March, the WKU team finished third overall after placing first in construction speed and third in stiffness, structural efficiency, economy and display. Before heading to nationals, the team has been making some modifications to improve the overall strength of it 18-foot beam bridge, Dr. Palmquist said.

The competitions and other projects prepare students for professional careers when they graduate. “We take a lot of pride in having our students get in the lab and get dirty,” he said.

Contact: Department of Engineering, (270) 745-2461.

Some of the links on this page may require additional software to view.